How Our Custom Lawn Mowers Help Eastern European Farms Save 40 Percent Operating Costs

Across Eastern Europe, agriculture is undergoing a transformation. Rising fuel costs, labor shortages, and tighter environmental standards are pushing farmers to look for smarter, more efficient equipment. In this climate, our custom-designed lawn mowers have emerged as a powerful tool to reduce operating expenses and improve productivity. As a Chinese manufacturer supplying agricultural machinery worldwide, we’re proud to share how our machines are saving Eastern European farms up to 40% in operational costs—and why this matters for the future of farming.

1 Understanding the Challenge in Eastern Europe

Many Eastern European farms still rely on outdated mowing equipment or even manual processes for pasture and field maintenance. This results in high fuel consumption, excessive labor hours, and inconsistent results. With increasing competition and pressure to maintain sustainability, finding a cost-effective mowing solution is essential.

2 Our Custom Lawn Mower Solution

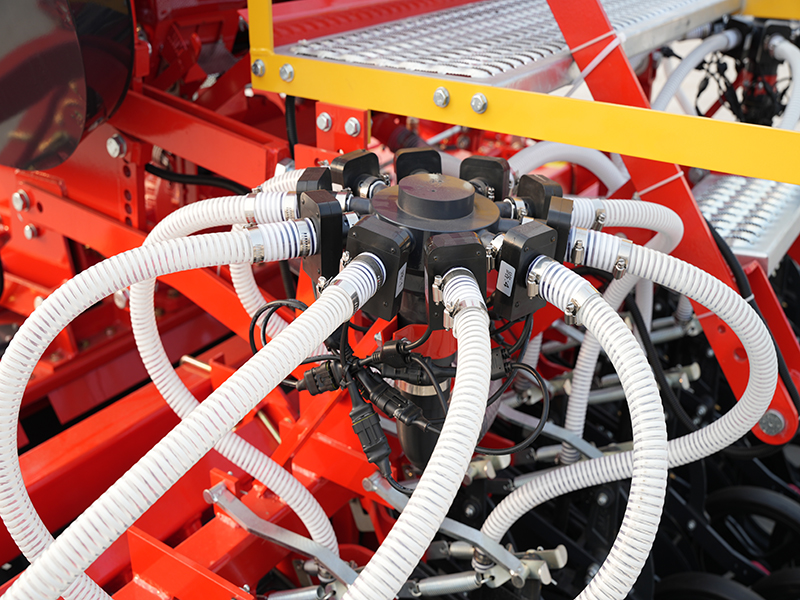

We developed our custom lawn mowers specifically for the demands of large and mid-sized farms in Eastern Europe. Designed for durability and efficiency, they feature high-efficiency cutting blades to reduce passes over the same area, fuel-saving engine technology optimized for long running hours, adjustable cutting widths to handle different terrains and crop residues, and easy-to-replace parts and minimal maintenance requirements.

By tailoring the machine to local conditions—such as soil type, grass density, and field size—we ensure maximum performance and minimum waste.

3 How Our Mowers Save 40% Operating Costs

The 40% savings come from three primary factors fuel efficiency our engine and blade design reduce fuel use by up to 25 percent, labor reduction one operator can cover more hectares in less time cutting labor costs, and maintenance savings robust construction and standardized components reduce downtime and repair expenses. Over a single mowing season these savings can add up to thousands of euros for a mid-sized farm.

4 Case Study Eastern European Farm Success

A large dairy farm in Poland replaced its old mowing fleet with our custom units. After one season they reported a 38 percent reduction in fuel costs and a 45 percent decrease in maintenance expenses. Productivity improved so much that two operators could do the work previously requiring four.

5 Frequently Asked Questions

Q1 How are these mowers different from standard models available locally

A Our mowers are engineered with high-torque low-emission engines and reinforced cutting decks specifically tested for Eastern European conditions.

Q2 Can the mowers handle uneven or rocky terrain

A Yes. We offer adjustable suspension and blade height to handle varying field conditions safely and effectively.

Q3 What is the delivery time to Eastern Europe

A Production typically takes 6–8 weeks and shipping adds another 3–5 weeks depending on location and customs clearance.

Q4 Do you provide after-sales support and spare parts locally

A Absolutely. We maintain partnerships with regional distributors for spare parts training and technical support across Eastern Europe.

Q5 How can farms finance these mowers

A We work with local banks and agricultural credit programs to help farmers access financing options for equipment purchases.

6 Environmental and Regulatory Benefits

Our mowers comply with EU emission standards and use biodegradable lubricants where possible. By reducing fuel consumption and emissions farms can not only save money but also demonstrate compliance with environmental regulations and sustainability initiatives.

7 Versatility for Multiple Applications

Beyond standard pasture maintenance our custom mowers can be used for roadside vegetation orchard floor management and even post-harvest field cleanup. This multipurpose functionality increases return on investment.

8 Total Cost of Ownership Matters

Many buyers focus on the initial purchase price but the real savings come from lower lifetime operating costs. With our custom lawn mowers farmers benefit from reduced fuel and labor costs longer service intervals and easy availability of parts through our local partners. This translates to a lower cost per hectare mowed over the machine’s lifespan.

9 Our Role as a Global Exporter

As a Chinese manufacturer we understand the challenges of international buyers. We handle everything from order customization and quality control to shipping customs documentation and on-site training. This turnkey approach ensures Eastern European farms receive equipment ready to work from day one.

10 Future Innovations in Mowing Technology

We’re investing in GPS-guided mowing systems hybrid powertrains and smart sensors to make mowing even more efficient. Eastern European farms adopting our current generation of mowers will be well-positioned to upgrade to these advanced features as they become available.

11 Recommendations for Farmers Considering an Upgrade

Before purchasing new mowing equipment evaluate your current cost per hectare for mowing fuel and maintenance records of existing equipment availability of local service support for new models financing options and long-term ROI. Our sales engineers are ready to help you perform this analysis and recommend the best configuration for your farm.

12 Conclusion

In today’s competitive agricultural environment efficiency is no longer optional it’s essential. Our custom lawn mowers empower Eastern European farms to save up to 40 percent in operating costs reduce environmental impact and improve productivity. As a trusted Chinese exporter we’re committed to delivering innovative cost-effective solutions tailored to your local conditions. By investing in smarter mowing equipment now farms can secure a sustainable and profitable future.

5. Get Your Personalized Solution Now

→ Call the selection hotline: +86 158 5359 8030 (also supports accessory customization inquiries).